+91-9891955655, +91-9810608025

abelectricals@hotmail.com

Induction Services

Leading Manufacturers, Exporters and Wholesaler of Induction Hardening Job work and Induction Heating Machine Repairing Service from Faridabad.

| Types Of Heat Treating | Induction Hardening |

| Techniques Of Heat Treating | Selective Heat Treating |

| Processes Of Hardening | Work hardening |

| Location | India |

| Payment Mode | Online / Offline |

| Product Name | Induction hardeining |

| Type | Induction Heating Unit |

| Application | Industrial Use |

| Automatic Grade | Manual |

| Country of Origin | India |

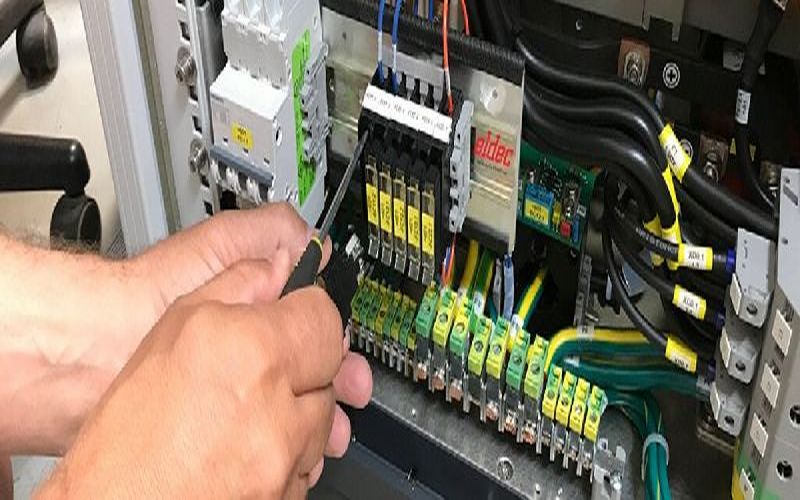

Capitalizing on the ability of our well-trained workforce, we are readily engaged in providing world-class Induction Heating Machine Repairing Service . A team of well-trained staffs is offering these services as per the thorough demands of our clients. We believe in offering precise solution of client’s needs and assist them accordingly.